PRODUCTS & SERVICES

SWS (Equipment Housing)

Inspection Systems

Semi-automatic system used for UT and VT testing of different kind of shells and walls. Consist of 3 different scanners - SWSM, SWST and SWSV.

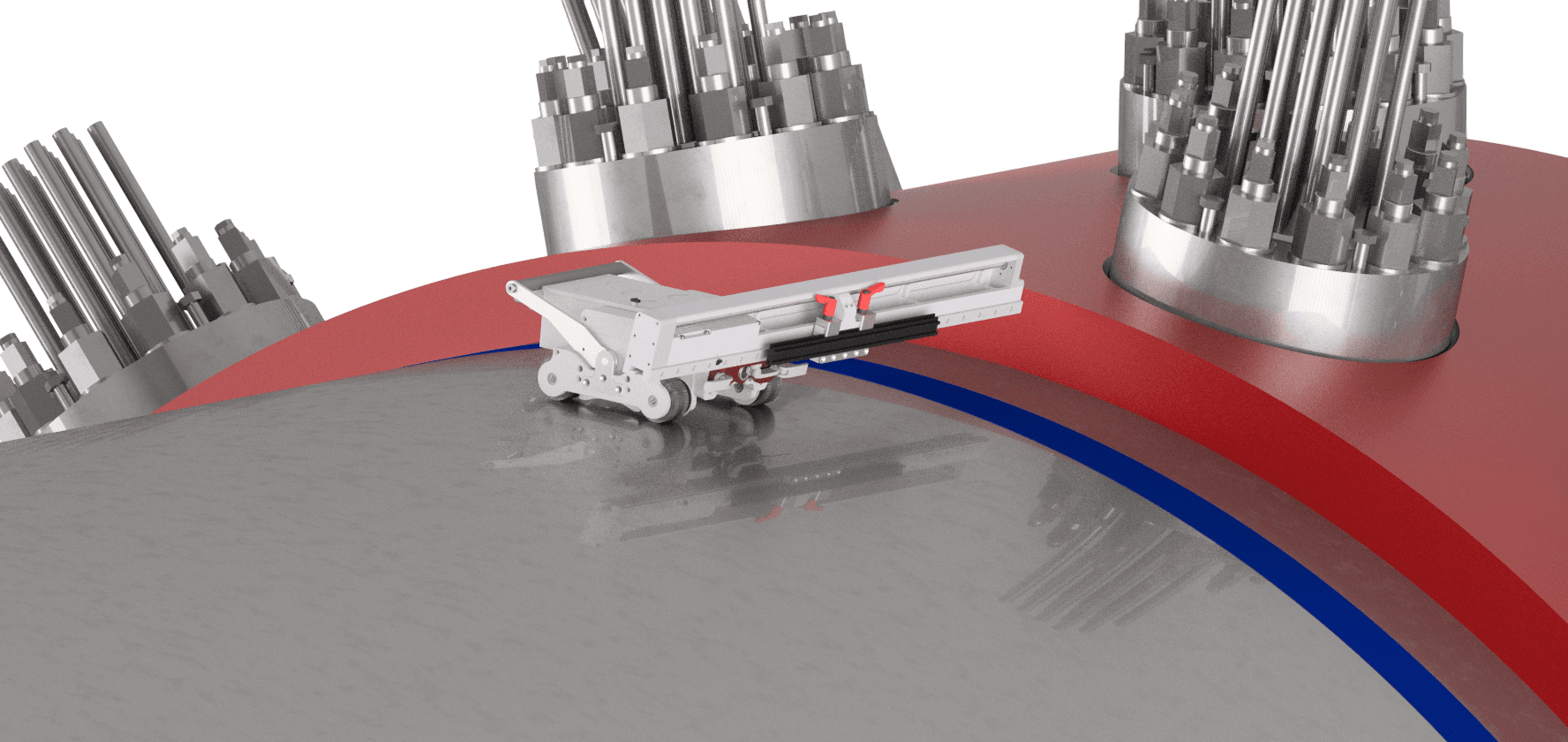

SWSM

A small-sized semi-automatic testing system powered by magnetic wheels, which is used for UT and VT testing of a vessel Shell material of vessels with magnetic walls, such as Steam generators, SAOZ i KD.

Key Features

- Quick, tool-free on-site setup using hands only.

- Operates on flat and curved cylindrical surfaces (min. diameter Rmin = 650 mm).

- Compatible with non-magnetic vessels using additional ring assemblies on vessel flanges (SPZAZ).

- Controlled by two servo axes:

- X-axis: linear drive via magnetic wheels

- Y-axis: transverse tool carrier movement (stroke = 565 mm)

- Supports simultaneous UT and VT inspections.

- Once mounted, the scanner is remotely operated for inspection.

- All modules and cameras are IP65-rated and radiation resistant.

SWST

A small-sized semi-automatic Inspection system used for UT and VT testing of vessel Shell material, where the working axes can be modularly rearranged into two different assemblies required for testing the corresponding zones.

Key Features

- Quick, tool-free on-site setup using hands only.

- X-axis drive runs on a circular mounting ring or segmental arc guide rail with magnetic holders.

- Two modular assemblies:

- Axial weld inspection relative to the scanner.

- Radial weld inspection with pneumatic cylinder, guides, and Y-axis attachment.

- Shared axes and guide rails for both assemblies; quick hand-screw adjustments for on-site setup.

- VT and UT inspection assemblies mounted on the Y-axis carriage.

- All modules and cameras are IP65-rated and radiation resistant.

SWSV

A small-sized semi-automatic Inspection system used for UT and VT testing of a vessel Shell material for non-magnetic vessels such as Barboter and SPAZ.

Key Features

- Quick, tool-free on-site setup using hands only.

- X–Y scanner design with shell grip via four vacuum suction cups on dual arch bridges.

- Suitable for UT inspections and partial VT inspections (welds only) across vessels with varying diameters.

- Interchangeable guide rails drive the carriage with UT and VT components over the test surface.

- Adaptable for edge surface inspections by repositioning the X-axis guide rail onto the supporting arch bridge near the amplifier housing.

- All modules and cameras are IP65-rated and radiation resistant.